High-quality images at large magnifications: fast, high-resolution lenses for large line sensors and area sensors

In the new “d.fine HR” product series, Qioptiq can provide high-resolution LINOS® d.fine HR 2.4/128mm 3.33x lens, which is suitable for demanding line sensors and area sensors. Due to its very high luminous intensity, it can provide a higher scanning speed, which is very suitable for high-end inspection tasks in industrial manufacturing. When the beam splitter and the lens are perfectly matched, the best coaxial line illumination can be achieved, which allows the line sensor to obtain a clear image with high contrast. In addition, its optional area module (d.fine HR area scanning module) also makes this high-resolution inspection lens very suitable for use with a two-dimensional area sensor.

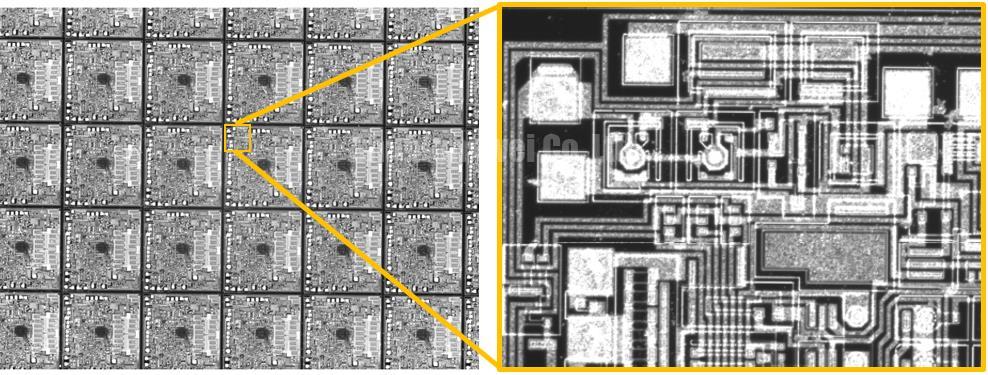

Figure 1 Qioptiq’s quality assurance: high-resolution inspection in industrial manufacturing also requires suitable precision optical components

The smaller and smaller tolerance ranges in industrial production place higher and higher requirements on optical inspection and quality assurance. In addition to industrial cameras with larger, higher-resolution image sensors, this also applies to required industrial lenses. In order to take full advantage of the high-resolution sensors of modern camera systems, high-performance optical components provided by professional manufacturers such as Qioptiq are required. The German subsidiary of Excelitas Technologies has expanded its existing product range and now offers high-resolution lenses with excellent imaging performance and high cost performance.

Perfect combination

In view of the high requirements in the field of machine vision, the production of each individual component is a big challenge. However, more critical is the interaction between components, assembly technology and adjustment systems. The entire production process chain must be perfectly coordinated, from specific glass, to optical design combined with mechanical design, to installation and measurement technology. Over the years, Qioptiq has accumulated rich experience in this interaction. Its new LINOS® d.fine HR2.4/128mm 3.33x lens is based on meltfit calculation; this means that every piece of glass used needs to be measured, and then the optical design is adjusted according to the specific glass melt. This is a necessary step because even the strictest tolerance levels provided by glass manufacturers are too large to guarantee high image quality in mass production. In addition, the position of each single lens element must be adjusted extremely accurately to achieve tilt, center, and positioning. Qioptiq has developed its own assembly technology for this purpose, which far exceeds the installation accuracy of the usual standard lens.

Very suitable for fully automatic inspection system

LINOS® d.fine HR 2.4/128mm 3.33x lens is aimed at manufacturers of image processing systems and automatic inspection equipment. Provided as a standard product, it can shorten the time to market for the next-generation inspection system because there is no need to consider the additional development time for custom lenses. Qioptiq also provides matching accessories for this lens: d.fine HR prism module, which can ensure the best coupling of coaxial illumination in line scan applications. Also, d.fine HR area scanning module can be used with area sensors. In addition, the d.fine HR standard system can accurately focus and is suitable for industrial cameras with M72, M90 and M95 threads. The total length of the lens and prism module can be controlled at 177.1 mm, and the total length of the lens with area scanning module can be limited to 146 mm. The optical performance of this new lens exceeds the widely recognized inspec.x L lens series on the market. The HR lens provides high-resolution, clear images with uniform high contrast in the entire image field, so it is very suitable for further Electronic processing.

Figure 2 For example, it has perfect resolution for inspecting the finest Circuit structures on a wafer

Its application areas include quality control in wafers, flat screens, OLEDs, printed circuit boards and glass production. Here, a large area must be scanned in a short period with a tolerance in the micrometer range. Due to its large aperture, this new d.fine HR lens has become an ideal choice for such applications, even in fast applications, it can provide sufficient light for the sensor. The lens has a focal length of 128 mm and a magnification of 3.33x, which can meet industrial requirements and can replace inspec.x L 4/105 3.5x. In addition, its working distance is relatively large, up to 60 mm, which provides flexibility for integration into various systems and applications.

Figure 3 The d.fine HR lens with prism module is used to couple coaxial illumination to ensure the highest imaging quality with 16k/5μm and 16k/3.5μm line sensors

Limited diffraction and no distortion

LINOS® d.fine HR 2.4/128mm 3.33x can achieve extremely high resolution, up to 300 line pairs per millimeter in the object. It is optimized for the 82mm image circle, so it is an ideal choice for long-line sensors (16k/32k) and medium-format large-area sensors (101MP/151MP). In addition, it also has an excellent color correction function to ensure high imaging performance straight to the edge. There is almost no distortion in the large image circle of 82 mm. Its nominal value is less than 0.1%, so no software correction function is needed.

The high aperture of 2.4 compared with the 3.33x magnification, and the resulting numerical aperture of 0.13, pushes the diffraction limit upwards, thereby providing high resolution and light intensity. This helps shorten the exposure time and speed up the production process, thereby increasing yield. This is the advantage of the new lens based on diffraction limited design. In comparison, the aperture of the inspect.x L series lens is f/3.5 or f/4.

German precision manufacturing

d.fine HR lens is the first lens in the LINOS machine vision lens series to support a pixel size as low as 3.5μm when the magnification is greater than 1. In comparison, the inspec.xL lens optimizes the pixel size of 5μm, theoretically achieves a maximum imaging performance of 50 LP/mm on the sensor, and has a contrast ratio of 38% under the spectral distribution of 420-680 nm. The new d.fine HR lens can also achieve these values at a speed of 72 LP/mm in the entire 82 mm image field. In order to maintain this high quality in mass production, a stable production process with high requirements for assembly and measurement technology must be used. Qioptiq uses a variety of proprietary assembly techniques to ensure that the optical components are precisely aligned, centered and fixed in position to meet strict tolerances. Qioptiq has the most advanced laboratories and measurement facilities to develop and manufacture high-quality inspection lenses. In addition to the MTF system of well-known manufacturers in the metrology industry, Qioptiq has also developed its own MTF system to show how to meet the special requirements of inspection lenses and support product development. In the new factory established in Feldkirchen near Munich, Germany in 2010, research and development, prototype manufacturing, series assembly and certification work are proceeding in parallel. The precision optical components of the lens are precisely manufactured, coated and tested using the latest technology in Regen in the Bavarian Forest Hills. This ultra-modern factory was completed and put into production in 2006.

Figure 4 MTF (modulation transfer function) d.fine HR 2.4/128 3.33x (left) 72 LP/mm

Figure 5 MTFinspec.x L 4/105 3.5x prism 50 LP/mm

Compared with Figure 5

100% acid test

All lenses must be 100% MTF tested before delivery, and certified for environmental requirements in accordance with the following ISO testing procedures.

Temperature: DIN ISO 9022-10-05-1 / 9022-11-05-1 / 9022-14-03-1

Impact resistance: DIN ISO 9022-31-01-0

Vibration resistance: DIN ISO 9022-36-07-1

This ensures that Qioptiq’s industrial lenses are sturdy and durable, can remain intact during transportation and storage, and function stably for a long time in harsh industrial environments.

Of course, LINOS® The d.fine series also meets the environmental protection requirements of modern industrial products and complies with RoHS and REACH standards. What makes Qioptiq even more proud is that it has been certified as a carbon neutral company since 2021, contributing to innovation and sustainable development.

Figure 6 Qioptiq has the most advanced machine vision lens manufacturing and testing facilities in Feldkirchen and Regen, Germany(Here: MTF measurement of the new HR lens)

Perfectly coordinated Modules

The HR lens provided by Qioptiq can be combined with a prism module or an area scanning module. The beam splitter prism brings great convenience to the configuration of the complete optical system composed of the lens and the illumination, because it can provide optical coupling for the coaxial illumination of the line scan camera. This is especially important for surfaces with high reflectivity, such as Displays or wafers. The lens and the dichroic prism must form an optical unit, and the components must be perfectly matched. The high optical requirements and installation technology of the prism are also critical here. Together, these components achieve the best limited diffraction imaging performance. The installation and connection of the lens, camera and prism can be completed through the V-shaped groove. This allows the orientation of the prism and the lens to be perfectly aligned, and the illumination can be adjusted precisely.

If there is no need to perform linear illumination through the prism module, it is necessary to compensate the glass thickness of the prism block, which has been considered in the lens design. The area scanning module can solve this problem. Its biggest advantage is that, depending on the additional module, the same lens can be used for line sensors and area sensors for coaxial illumination.

Lens viewfinder for industrial image processing

Qioptiq can provide MachVi software to help users choose the right lens. By downloading free software, all necessary optical parameters can be calculated according to the four specifications of object size, working distance, sensor size and camera bracket, and from the LINOS machine vision series Choose the right lens and the necessary mechanical components.

Summarize

With LINOS machine vision lenses, Qioptiq meets the highest standards of current industrial lenses. The continuous development of sensor technology pushes users to put forward higher requirements for resolution lenses. Sensors are getting larger and larger, but the pixel size is constantly decreasing, so as to meet more demanding measurement tasks. This also increases the user’s requirements for optical components, which must ensure that it has a corresponding high resolution in the entire image field. With LINOS® d.fine HR 2.4/128mm3.33x, Qioptiq provides the market with a lens that can perfectly meet current needs.

Key words:

‘); (window.slotbydup=window.slotbydup || []).push({ id: ‘3303971’, container: s, size: ‘20,5’, display:’inlay-fix’ }); })();