Mitsubishi PS11016 IPM: A Technical Review for Integrated Motor Control

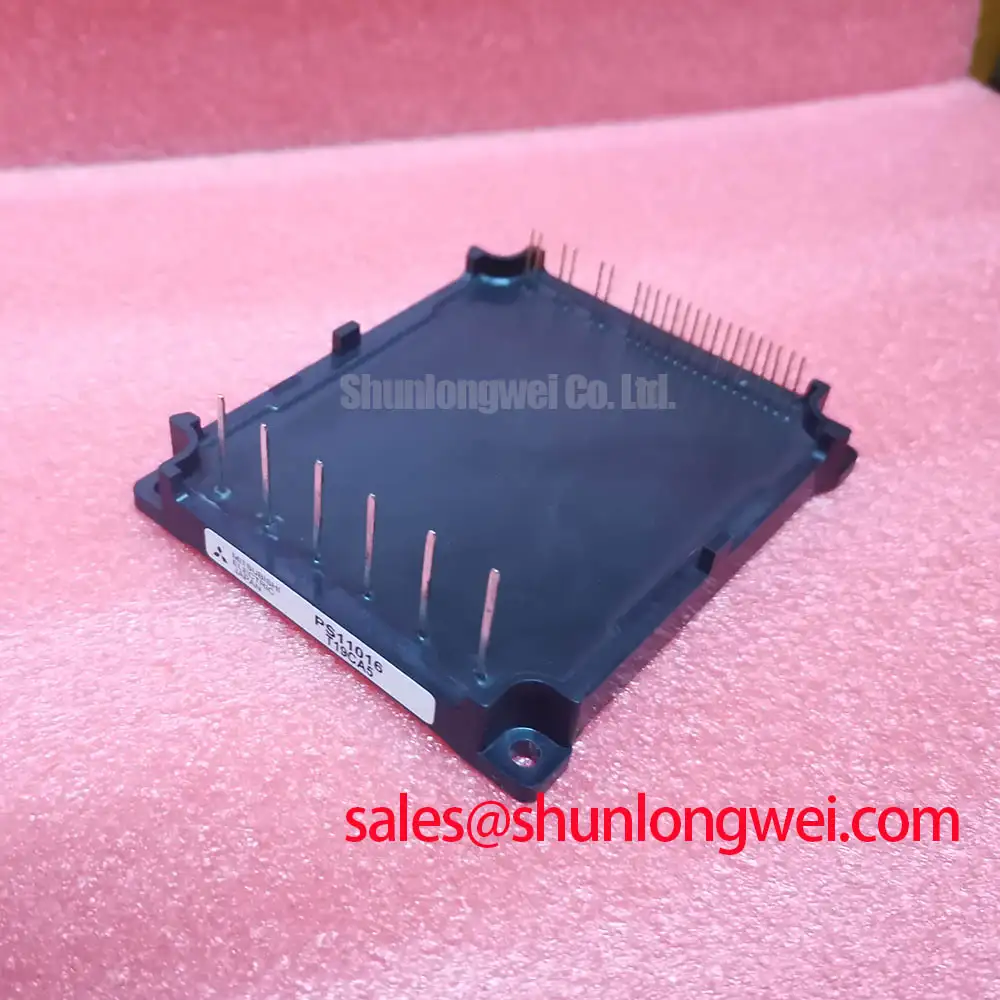

Mitsubishi PS11016 600V/30A DIP Intelligent Power Module

Introduction and Core Highlights

The Mitsubishi PS11016 is a highly integrated Application Specific Intelligent Power Module (IPM) that consolidates a complete 3-phase IGBT inverter bridge, a dynamic braking circuit, and optimized gate drive and protection circuitry into a single compact flat-base package. This level of integration provides a robust solution for simplifying the design of motor control applications up to 2.2kW, significantly reducing PCB complexity and enhancing overall system reliability. It addresses the critical engineering need for a space-saving power stage without compromising on protective features.

- Core Specifications: 600V | 30A | 3-Phase + Brake IGBT

- Key Advantages: Reduces component count with integrated gate drivers and bootstrap diodes; enhances system safety with built-in short-circuit, under-voltage, and over-temperature protections.

Download the Official PS11016 Datasheet (PDF)

Technical Analysis: Integration as a Design Accelerator

The principal engineering value of the PS11016 is its system-in-a-package design. By co-packaging the power switches (IGBTs and FWDs) with dedicated high-voltage and low-voltage ICs (HVIC/LVIC) for gate driving, the module eliminates significant design overhead. This integration removes the need for external gate driver components and complex high-voltage level-shifting circuitry. The inclusion of bootstrap diodes further streamlines the power architecture, enabling the high-side IGBTs to be driven from a single control power supply, a critical feature for reducing PCB footprint and BOM cost in designs like those found in modern factory automation.

The comprehensive, built-in protection suite is another cornerstone of its design. The module provides short-circuit (SC) protection for both P-side and N-side IGBTs, under-voltage (UV) lockout for the control supply, and system over-temperature (OT) protection. Think of this as an integrated safety supervisor for the power stage. It constantly monitors for hazardous conditions and can trigger a fault output (FO) signal to the system’s microcontroller, allowing for an orderly shutdown before a catastrophic failure can occur. This level of integrated protection is fundamental to building reliable systems.

Optimized Application Scenarios

The feature set of the PS11016 makes it a precise fit for several specific applications:

- Air Conditioners & Home Appliances: The compact, single-package design is ideal for the space-constrained enclosures of consumer goods, while the integrated over-temperature protection ensures operational safety during long-duty cycles.

- Small General-Purpose Inverters: For AC motor drives up to 2.2kW, the module provides a complete, protected power stage, simplifying the design of Variable Frequency Drives (VFDs).

- Servo Drives: The optimized internal gate drivers ensure controlled switching of the IGBTs, which is critical for achieving the precise motion control required in servo applications.

- Motor Control with Regenerative Braking: The inclusion of a dedicated brake circuit IGBT allows for the efficient management of energy returned from the motor during deceleration, a common requirement in industrial motion control.

Its blend of power density, integrated control, and comprehensive protection makes it an optimal solution for compact motor drives requiring high operational reliability.

Key Specification Parameters for the PS11016

| Parameter | Value | Conditions |

|---|---|---|

| Absolute Maximum Ratings (Tj = 25°C unless otherwise noted) | ||

| Collector-Emitter Voltage (VCES) | 600V | – |

| Collector Current (IC) | 30A | – |

| Collector Power Dissipation (Pc) | 89W | TC = 25°C, per IGBT |

| Junction Temperature (Tj) | -20°C to +150°C | – |

| Isolation Voltage (Viso) | 2500Vrms | AC 60Hz, Sinusoidal |

| Electrical Characteristics (Tj = 25°C, VCC = 15V) | ||

| Collector-Emitter Saturation Voltage (VCE(sat)) | 2.2V (Typ) / 2.7V (Max) | IC = 30A |

| Short-Circuit Protection Trip Level (SC) | 45A (Typ) | VCC=15V, Tj=125°C |

| Control Supply Under-Voltage Protection (UV) | 12.5V (Trip) / 13.0V (Reset) | – |

| Over-Temperature Protection (OT) | 125°C (Trip) | – |

| Thermal Characteristics | ||

| Thermal Resistance (Rth(j-c)) | 1.4°C/W (Max) | Junction to Case, Inverter IGBT |

Note: The parameters listed are summary points. Engineers must consult the official PS11016 datasheet for complete specifications and application notes.

Engineer’s FAQ

- 1. How can I design a compact 3-phase inverter using the PS11016?

- The PS11016’s high integration is key. Because the gate drivers, bootstrap circuits, and protection logic are internal, you can significantly reduce the PCB area typically required for these functions. Refer to the application circuit in the datasheet, ensuring short, wide traces for the main power paths and placing bypass and bootstrap capacitors as close to the module pins as possible to minimize inductance.

- 2. What are the thermal design considerations for this module?

- The module has a maximum junction-to-case thermal resistance (Rth(j-c)) of 1.4°C/W for an inverter IGBT. A heatsink is required for proper thermal management. Calculate the total power dissipation based on your application’s switching frequency and load current, then select a heatsink with an appropriate thermal resistance (Rth(c-f) + Rth(f-a)) to keep the maximum junction temperature below the 150°C limit specified in the datasheet.

- 3. How does the module signal a fault condition?

- The PS11016 provides dedicated fault output (FO) pins. In the event of a short-circuit, under-voltage, or over-temperature condition, the corresponding FO pin will be driven low. This active-low signal can be directly connected to a microcontroller’s interrupt pin to trigger an immediate and safe system shutdown procedure in the control software.

Enabling Reliable and Compact Power Design

The Mitsubishi PS11016 delivers a complete power stage solution that empowers engineers to develop more compact, reliable, and cost-effective motor control systems. By integrating the most critical drive and protection functions into a single, thermally efficient package, it streamlines the design process, allowing for faster development cycles and resulting in a more robust end product. For further reading on power module technologies, explore the differences between a PIM vs. a discrete IGBT approach.