Vicor V300B12H250BL: A High-Density 250W DC-DC Converter Analysis

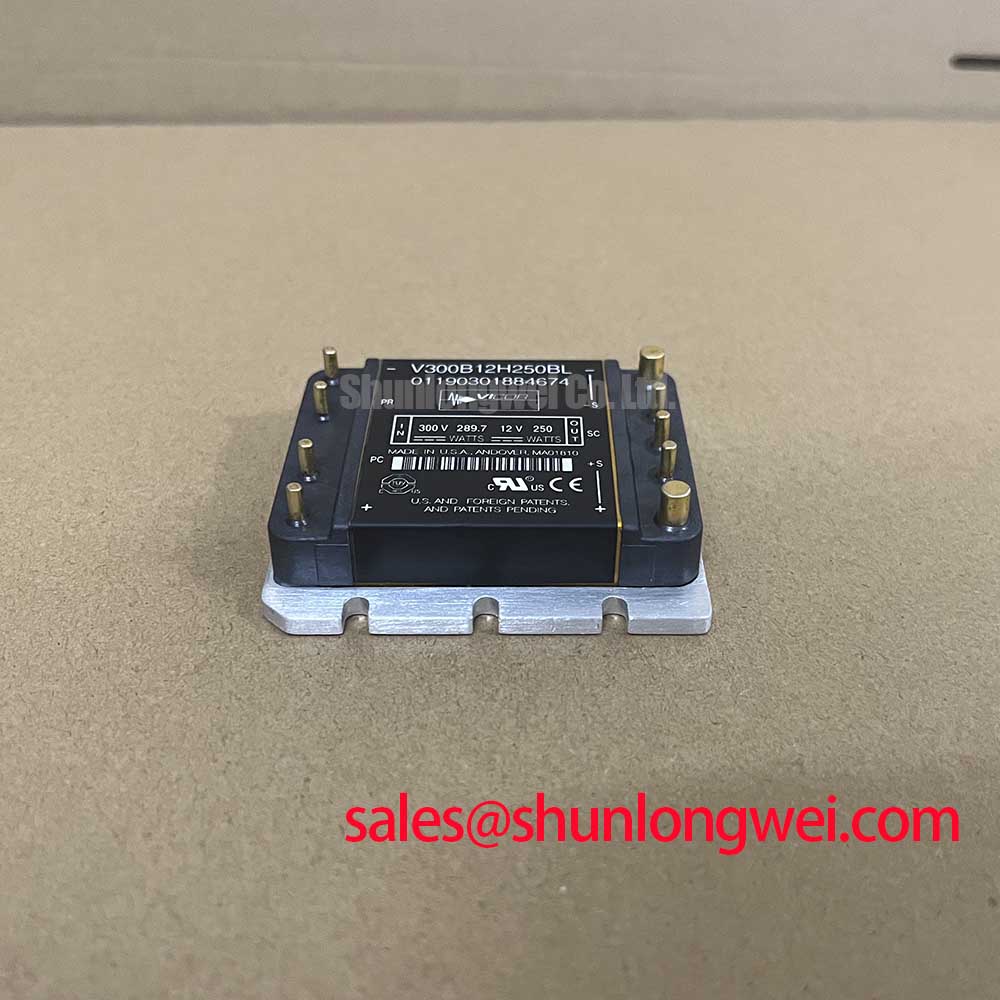

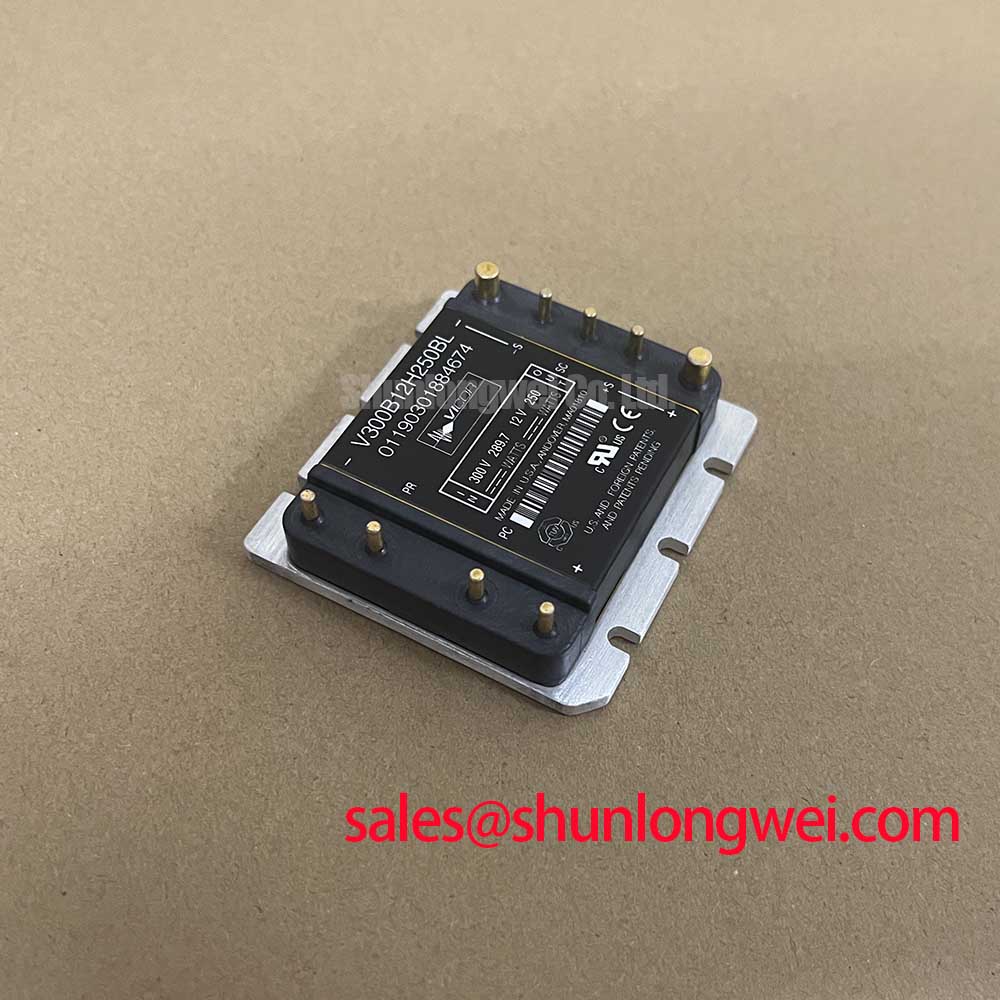

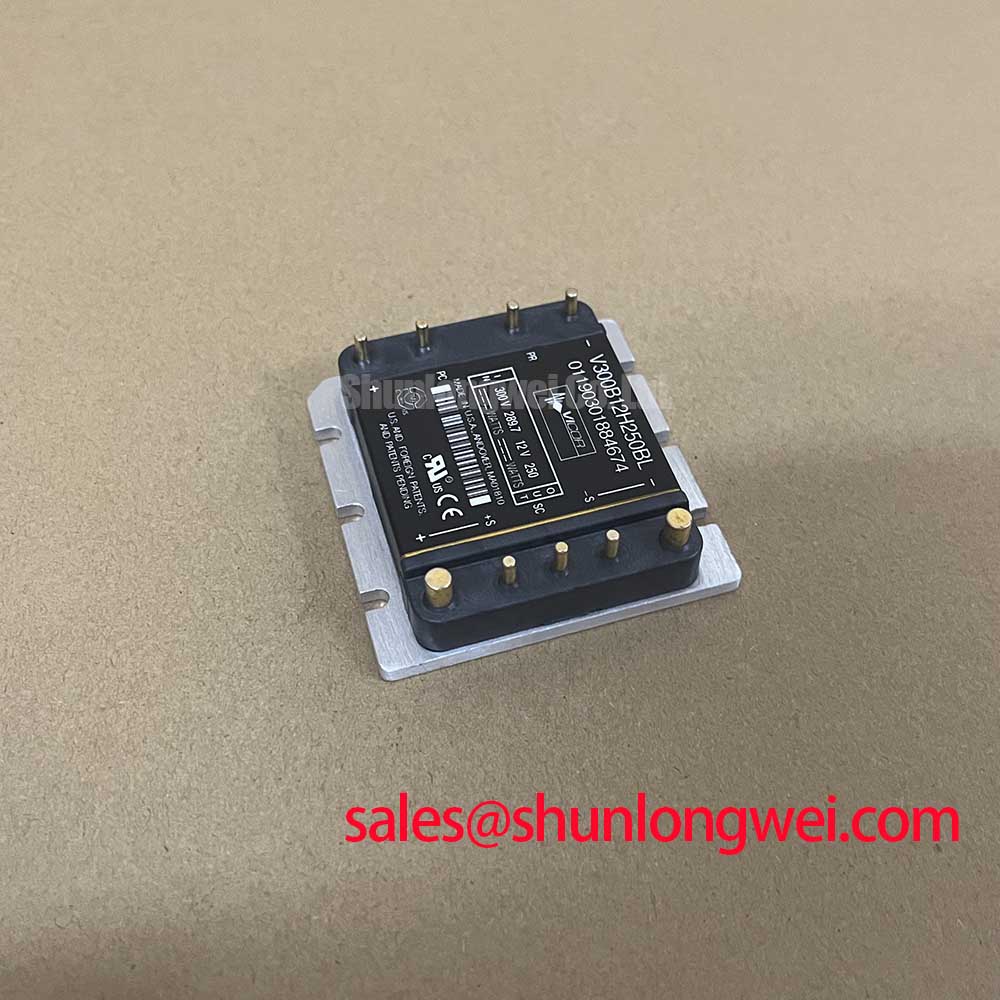

Vicor V300B12H250BL 250W DC-DC Converter Module

High-Density Power Conversion with ZCS/ZVS Architecture

The Vicor V300B12H250BL is an isolated DC-DC converter module engineered for high efficiency and power density. Its core value proposition lies in the use of a high-frequency Zero-Current Switching/Zero-Voltage Switching (ZCS/ZVS) architecture, which enables it to deliver 250W of output power from a compact “Mini” size package. This approach significantly reduces switching losses, contributing to higher efficiency and simplified thermal management in demanding applications.

- Core Specifications: 180-375V DC Input | 12V DC Output | 250W Power

- Key Advantages: High power density up to 100W/in³, low noise output.

- Engineering Value: Reduces required board space and minimizes the need for external cooling hardware.

For engineers evaluating power components, understanding the implications of topology is key; the ZCS/ZVS method allows for efficient operation across the entire input voltage range. Download the official datasheet (PDF).

Technical Analysis: Power Density and Efficiency

The standout feature of the V300B12H250BL is its exceptional power density. Delivering 250W from a package measuring just 2.28″ x 1.45″ x 0.5″ is a direct result of its advanced switching topology. Think of the ZCS/ZVS architecture as a seamless gear shift in a high-performance vehicle; it engages the power transistors at moments of zero current or voltage. This minimizes the energy wasted as heat during each switching cycle, which is a common issue in conventional “hard-switching” converters. The result is an efficiency of up to 88%, which directly translates to less waste heat.

This efficiency has profound implications for system design. A cooler-running module enhances overall system reliability and longevity. The low thermal footprint, a key aspect of effective thermal management, means engineers can often rely on smaller heatsinks or, in some cases, only conduction or convection cooling. This saves not only component cost but also valuable physical space and weight in the final product. The module’s wide operating temperature range, up to 100°C at the baseplate, is a testament to this thermally efficient design.

Optimized Application Scenarios

The V300B12H250BL is well-suited for a range of high-reliability applications where space and efficiency are critical parameters. The selection of suitable power semiconductors is crucial for system performance.

- Industrial and Process Control: Its wide input range of 180-375V DC easily accommodates fluctuations typical in factory power buses.

- Distributed Power Architectures: The module’s high density and isolated output make it an excellent choice for creating localized, regulated voltage rails from a higher voltage bus, reducing system-level noise and complexity.

- Automated Test Equipment (ATE): Low output noise, a characteristic of ZCS/ZVS architecture, is essential for providing clean power to sensitive measurement instruments.

- Defense and Aerospace: The module’s robust design and broad operating temperature range (-40°C to 100°C) ensure reliable performance in harsh environments.

This module is an optimal match for systems requiring a reliable, high-density, isolated 12V source from a wide-range high-voltage DC input.

Key Specifications of the V300B12H250BL

| Parameter | Value |

|---|---|

| Input Voltage Range | 180 – 375 VDC |

| Output Voltage | 12 VDC |

| Output Power | 250 W |

| Maximum Output Current | 20.83 A |

| Efficiency (Typical) | 88% |

| Isolation Voltage (Input to Output) | 3000 VRMS |

| Operating Temperature (Baseplate) | -40°C to +100°C |

| Dimensions | 2.28″ L x 1.45″ W x 0.5″ H (57.9 x 36.8 x 12.7 mm) |

Note: All specifications are based on the official manufacturer’s datasheet. For detailed characteristics and application guidance, please refer to the document.

Engineer’s FAQ

1. What is the primary benefit of the ZCS/ZVS topology in the V300B12H250BL?

The main benefit is high efficiency, which leads to reduced heat generation. This allows the module to achieve very high power density and often simplifies or reduces the required external cooling components, saving space and cost.

2. What are the key thermal considerations when integrating this module?

The module is rated for operation up to a baseplate temperature of 100°C. A proper thermal path from the module’s baseplate to a heatsink or chassis is critical. The datasheet provides thermal resistance figures to help calculate the required heatsink performance based on the application’s load and ambient temperature.

3. Can the V300B12H250BL modules be connected in parallel?

Yes, the datasheet confirms that these modules are parallelable. This allows for scaling power output to meet higher demands and can be configured for N+M fault tolerance, which is critical for building highly reliable systems. For guidance on paralleling, consulting the manufacturer’s design guides is recommended.

4. How is the output voltage adjusted?

The output voltage is programmable from 10% to 110% of its nominal value. This is typically achieved by connecting external resistors, as detailed in the official product documentation. Exploring options in advanced diagnostics and configuration can provide further insights into system control.

Enabling Compact and Reliable Power Systems

The V300B12H250BL DC-DC converter provides a robust solution for engineers tasked with designing power systems where performance cannot be compromised by size constraints. Its blend of a wide input range, high power density, and efficient operation facilitates the development of smaller, lighter, and more reliable end products. This module empowers the creation of sophisticated power conversion stages within demanding industrial and high-reliability environments.